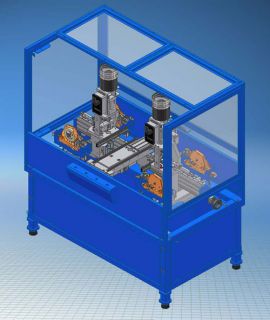

Super Dual

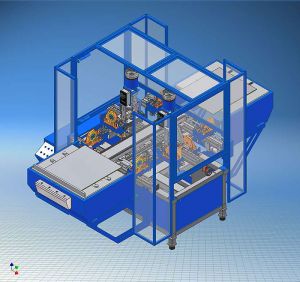

Machine for automatic drilling, pinning and taping of Duble Sided Boards. Pinning and taping operation of multi-layer boards.

Technical data

- Panel sizes: min 450 x 450 mm max 650 x 750 mm.

- Stack thickness sizes: min. 3 mm , max 11 mm .

- Pin length maximum pin length 19 mm maximum length under back up 16 mm .

- Pin feed: automatic with two electromagnetic pin feeder.

- Pin load: automatic , motion on linear bearing .

- Pin insertion: pneumatic with flow control.

- Stack drilling: by means of two independent electro-drilling heads with moving quill.

- Vacuum bells: in built on pinning platform.

- Pressure foot function: automatic, in cycle.

- Self height adjustment of pin punchers.

- Referencing system: against railing stoppers on Y axis with spring loaded dog at the opposite end.

- Against side dog with micrometer adjustment on X axis.

- PLC controlled cycle

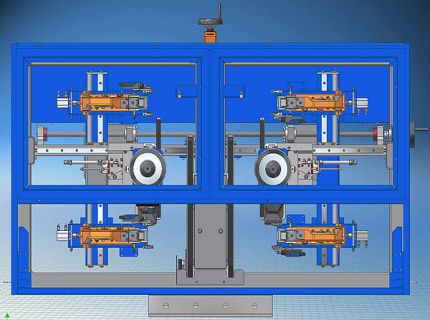

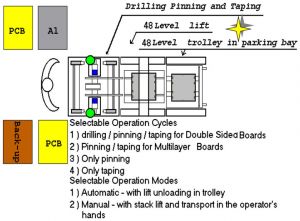

Working mode

Operator can select:

- DRILLING,PINNING,TAPING for Double sided Boards. Cycle 12 seconds.

- PINNING,TAPING for Double sided Boards or Multi-layers Boards. Cycle 9 seconds.

- ONLY PINNING for Double sided or Multi-layers Boards. Cycle 9 seconds.

- ONLY TAPING for Double sided or Multi-layers Boards. Cycle 5 seconds.

- All cycle times include unloading operation

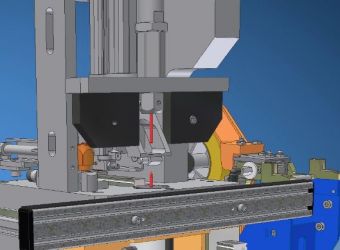

Taping heads

- Four NORTH STAR Taping Heads.

- Standard paper tape rolls.

- Cycle time less than 3 seconds.

- No Adjustments required for stack taping from 3 to 11 mm.

- Motion on linear guide-ways.

- Taping length 5 mm ( Top ) 10 mm ( under back up ).

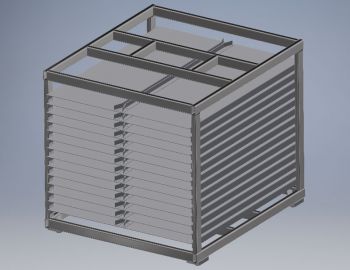

Automatic unloading system

The working cycle is completed with the unloading operation, performed by a lift and a belt transport system.The total cycle time for the longest cycle D/P/T including unloading is 12 seconds.The unloading direction can be selected:

- Towards the operator for manual operation

- Towards lift/trolley in Flexible system configuration.

Compliance

Compliance with the Electromagnetic Compatibility Directive 89/336/ECC, in the Low Voltage Directive 93/68/ECC and following amendements.

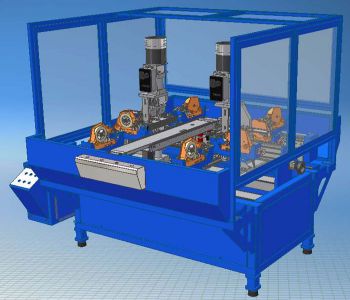

Stack Master

|

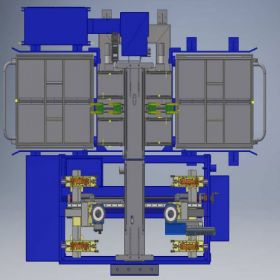

Machine for high precision automatic drilling ,pinning and taping of double sided and/or multi-layers boards.

Basic configuration STACK MASTER 4-PT (PINNING & TAPING) STACK MASTER 8-PT (PINNING & TAPING)

|

|||||||||||||||||||||||||||||||||||||||||

|

The machine is equipped with:

|

|||||||||||||||||||||||||||||||||||||||||

|

MULTI LAYER BOARDS

DOUBLE SIDED BOARDS

|

|||||||||||||||||||||||||||||||||||||||||

|

Machine designed for the stack assembly operation of Double faced boards and/or Multi-layers boards with the simultaneous execution of the above mentioned operation cycles. TAPING HEADS

PINNING HEADS

CENTRING HEADS

Technical data Panel sizes: STACK MASTER 8-DPT (DRILLING - PINNING - TAPING)

Compliance |

|

||||||||||||||||||||||||||||||||||||||||

Systems

STACK MASTER 2018 - AUTOMATION SOLUTIONS

STACK MASTER 2018 – BASIC MODULE – STAND ALONE INSTALLATION

It is possible to add different automation modules to the standard stand alone Stack

Master in order to configure your automation project.

Here are some examples:

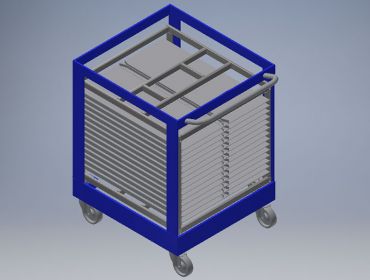

CONFIGURATION nr.1

Manual loading

Flexible auto unload selection:

A ) Stack returns in the operator’s hand

B ) Stack is automatically unloaded on the lift ( 16-24-32-48 levels )

Batch Management- Production log- average production times - etc

Fast batch size change over

In this configuration the average production of a 92 stacks batch with stack factor 3 composed of :

- 1 back-up

- 3 pcb

- 1 Entry foil

- Is over 3 stacks/min

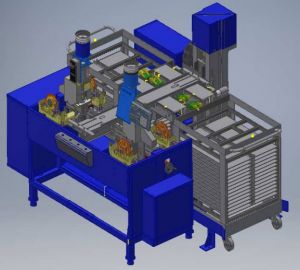

CONFIGURATION nr. 2

Pre-Centring station

Stack Transport system

Basic outlet station to be configured on different choices :

- Lift + Trolley

- Lift + Trolley & Cage ( 6 or 12 levels )

- Dual outlet left and right stack exits for delivery to buffer cages

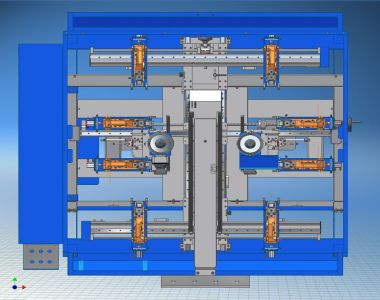

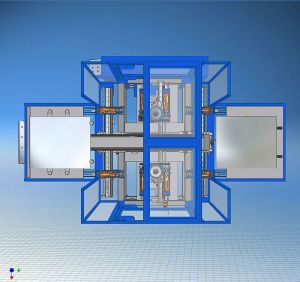

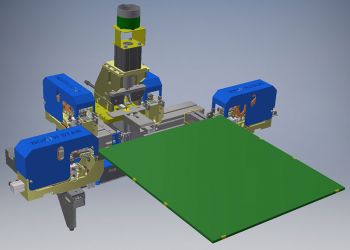

TOP VIEW - STACK MASTER 2018 – BASIC MODULE +PRE-CENTRING STATION+OUTLET STATION

CONFIGURATION nr. 2 cont.

SIDE VIEW - STACK MASTER 2018 – BASIC MODULE +PRE-CENTRING STATION+OUTLET STATION

In this configuration the average production of a 92 stack batch with stack factor 3 composed of :

- 1 back-up

- 3 pcb

- 1 Entry foil

- Is close to 4 stacks/min

CONFIGURATION nr.3

Note : In this configuration the system tapes only in the short sides of the stack, and therefore can serve machines equipped with side mushroom clampers

- Operator loads stack on main platform and orders the pinning and taping operation

- Stack Transport system will take pinned stack to the lift with a sorting station platform that will unload in the selected mode :

a) Left-right

b) Only left

c ) Only right

There are different possibilities

- Trolley 16 levels

- Trolley & Cage ( 6 or 12 levels )

TOP VIEW

STACK MASTER 2018 – BASIC SHORT SIDE TAPING MODULE + STACK TRANSPORT

SYSTEM +OUTLET STATION+PARKING BAY+ Nr 2 TROLLEYS with CAGES

CONFIGURATION nr.3 cont.

VIEW

STACK MASTER 2018 – BASIC SHORT SIDE TAPING MODULE + STACK TRANSPORT

SYSTEM +OUTLET STATION+PARKING BAY+ Nr 2 TROLLEYS with CAGES

In this configuration the average production of a 92 stack batch with stack factor 3

composed of :

- 1 back-up

- 3 pcb

- 1 Entry foil

- Is over 3 stacks/min

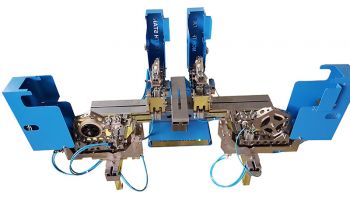

QUICK FOUR PT ( Pinning & Taping System for MLB )

Dedicated to small volume production this system delivers an high performance Pinning and taping Multilayered Boards .

The lay-out of this system allows simultaneuos:

Taping short side ( two tape strips )

Taping long side ( two tape strips )

Automatic centring and pinning

Total direct time 2 seconds

The system requires a second operation to complete a stack